Surface improvement

November 17, 2023 2023-11-17 17:21Surface improvement

Surface improvement

The fine-tuning of the application-specific and customer-specific appearance of our electronics enclosures is created by the marking of the operating elements and the applying of company logos etc. Depending on the material used for the enclosures, and the scope of the series of enclosures, different printing processes, or also laser marking, are available for use. The decision regarding the optimal process depends on the individual choice of colours, the place of intended use, and the number of enclosures which are to be designed. Just ask us for advice!

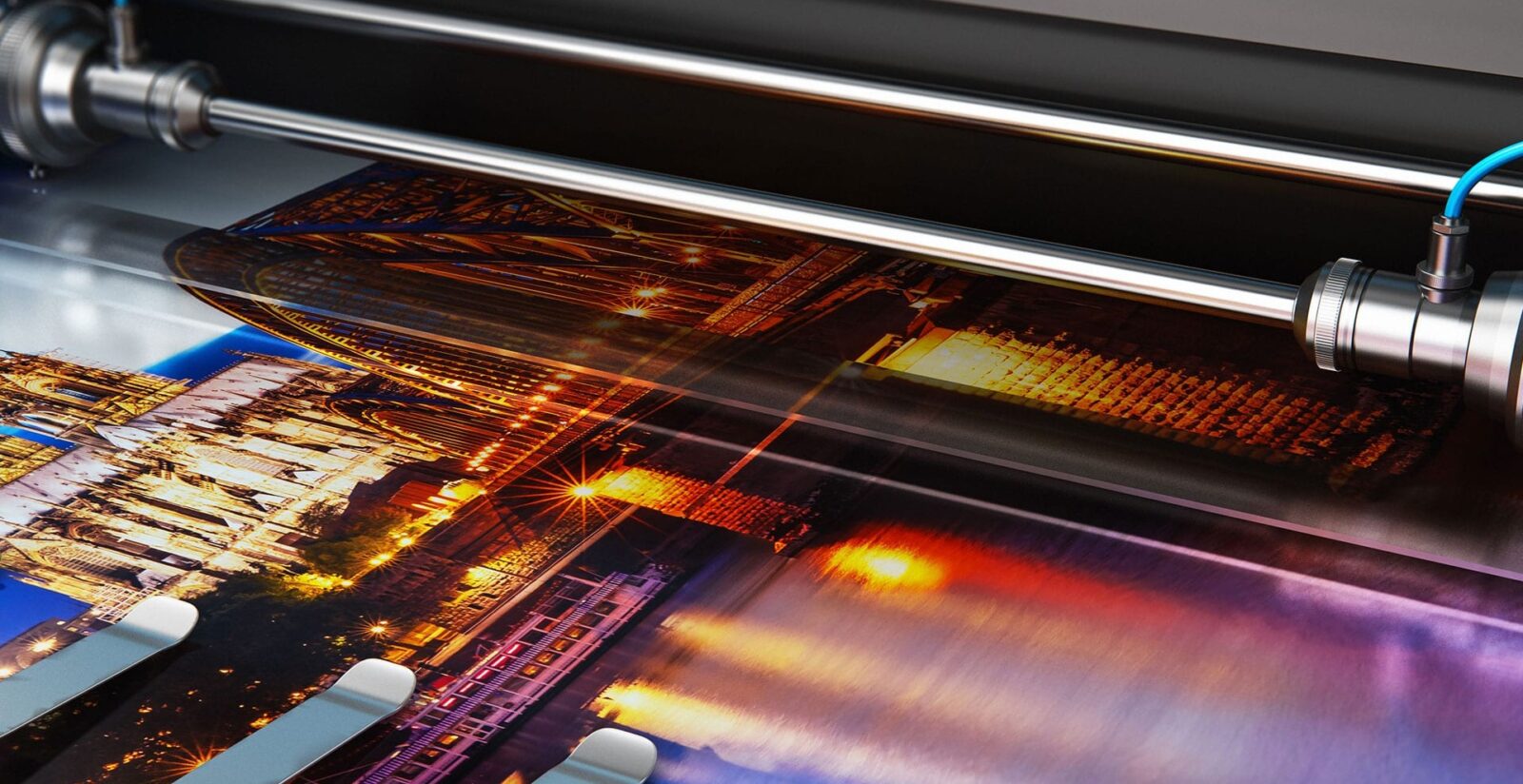

Digital printing

The flexible printing process for designing user-specific electronics enclosures.

Representation of photorealistic designs / colour gradients

Low set-up costs

Representation of photorealistic designs / colour gradients

Low set-up costs

Laser marking

Thanks to the innovative laser process, even changing layouts during every marking procedure is not a problem.

The laser can easily operate on uneven surfaces which are normally problematical for printing

Silk screen and pad printing

We use silk screen and pad printing in accordance with your specifications in RAL, Pantone or HKS colours. Our modern machinery and high-quality ink guarantee optimal print quality.

Engraving

Engraving involves the cutting of letters or images in aluminium and plastic components, for example in enclosures, part front panels, plug-in front panels and profiles.