Revolutionizing Asset Tracking with Long-Range, Low-Power Sensor Technology.

Revolutionizing Asset Tracking with Long-Range, Low-Power Sensor Technology.

In today’s industrial landscape, effective asset tracking and data management are crucial for operational efficiency, safety, and overall business success. With the rise of IoT technologies, long-range, low-power sensors have emerged as a game-changing solution, offering robust tracking, monitoring, and management capabilities in even the harshest environments.

These sensors, such as the Remote Link Connect Industrial Tracker, provide industries with the tools they need to optimize asset usage, enhance safety, and make data-driven decisions.

Built for Durability and Reliability

Industrial environments present a unique set of challenges, from extreme temperatures to exposure to dust and water. To meet these demands, long-range, low-power sensors are designed with durability and reliability in mind.

The Remote Link Connect Industrial Tracker, for example, boasts an IP65 rating, making it dust-proof and resistant to powerful water jets. This level of protection ensures that the device can operate effectively in outdoor settings, industrial facilities, and agricultural environments where conditions can be unpredictable and demanding.

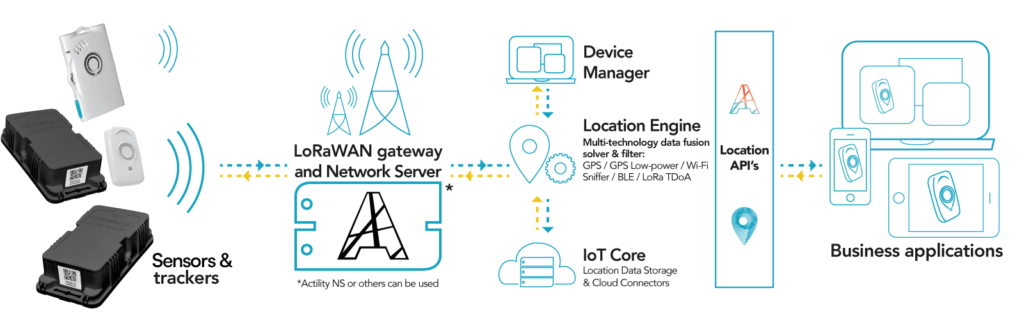

In addition to their rugged design, these sensors are equipped with advanced features that enhance their functionality. The incorporation of LoRaWAN™ Class A radio technology allows for long-range communication, ensuring that data can be transmitted over vast distances without the need for extensive infrastructure. Moreover, the firmware can be upgraded, ensuring that the device remains up-to-date with the latest advancements in sensor technology.

Versatile Applications Across Industries

One of the standout features of long-range, low-power sensors is their versatility. These devices can be deployed in a wide range of applications, making them an invaluable tool across various industries.

Real-Time Asset Tracking and Monitoring

In industrial settings, the ability to track and monitor assets in real-time is critical. Whether it’s heavy machinery, vehicles, or light assets, these sensors provide accurate, up-to-the-minute data on location and status. This real-time tracking capability not only improves operational efficiency but also reduces the risk of asset loss or theft.

Agricultural and Livestock Monitoring

The agricultural sector also benefits from the deployment of these sensors. Large-scale farms, in particular, require reliable methods for tracking livestock over vast areas. The Remote Link Connect Industrial Tracker excels in this environment, providing precise location data that helps farmers manage their herds more effectively. Additionally, the device’s geofencing capabilities allow farmers to set virtual boundaries, receiving alerts if livestock wander beyond designated areas.

Supply Chain Optimization

In the realm of logistics and supply chain management, efficiency is key. Long-range, low-power sensors can be integrated into the supply chain to optimize processes such as production, inventory management, and delivery. By providing real-time data on the movement and status of goods, these sensors help businesses streamline operations, reduce costs, and improve customer satisfaction.

Enhanced Safety and Proactive Maintenance

Safety is a top priority in any industrial operation. Long-range, low-power sensors contribute to enhanced safety by enabling precise monitoring and control of assets and equipment. The Remote Link Connect Industrial Tracker, for instance, offers BLE-based safe and hazard zone detection, allowing businesses to create safety zones within their facilities. If an asset or individual enters a hazardous area, the system can trigger alerts, helping to prevent accidents and ensuring compliance with safety regulations.

In addition to safety, these sensors support proactive maintenance strategies. By continuously monitoring the condition and activity levels of assets, businesses can identify potential issues before they lead to costly breakdowns. This proactive approach to maintenance not only extends the life of critical equipment but also minimizes downtime, further contributing to operational efficiency.

Leveraging Data for Informed Decision-Making

The true power of long-range, low-power sensors lies in their ability to collect and transmit data in real-time. When integrated with a comprehensive management system like Remote Link Connect, this data can be used to drive informed decision-making across the business. Whether it’s optimizing asset usage, improving supply chain logistics, or enhancing safety protocols, the insights provided by these sensors enable businesses to operate more efficiently and effectively.

Furthermore, the multiple operating modes of these sensors—such as motion detection, permanent tracking, and fix-on-demand—provide flexibility in monitoring and data collection. This adaptability ensures that businesses can tailor their tracking and monitoring strategies to meet specific needs, whether it’s maintaining constant oversight of high-value assets or conducting periodic checks on less critical equipment.

Embracing the Future of Industrial Operations

As industries continue to evolve, the adoption of long-range, low-power sensors is becoming increasingly essential. These devices not only provide reliable and accurate tracking and monitoring but also empower businesses with the data needed to optimize operations, enhance safety, and make informed decisions. By integrating these sensors into your industrial operations, you can stay ahead of the competition, reduce costs, and take full advantage of the benefits that IoT technology has to offer.

Are you ready to revolutionize your asset tracking and data management strategies? Visit RemoteSource.net to discover how our long-range, low-power sensors can transform your business.